Coop Agri-Énergie Warwick is the very first agricultural cooperative dedicated to renewable energy production in Quebec. It brings together a dozen agricultural producers from the Arthabaska MRC who produce renewable natural gas (RNG) from slurry and dairy cattle manure mixed with residual organic matter from surrounding businesses.

The anaerobic digestion complex is operated and has been developed and built by Coop Carbone, a non-profit solidarity cooperative that develops cooperative agricultural biogas projects.

The anaerobic digestion complex has been built on the Kirouac road in Warwick, in Centre-du-Québec region. The site was chosen because of the high concentration of dairy farms in the surrounding area and its proximity to the gas grid. In addition, in its environmental policy, the town of Warwick supports biodigesting as a measure to reduce the use of fossil fuels.

Many agricultural regions in Quebec have similar potential for renewable natural gas (RNG) production, other cooperatives of this type are set to emerge. Contact Coop Carbone for more details.

Coop Agri-Énergie Warwick is an agricultural cooperative that ensures the full participation of agricultural producers and a fair redistribution of wealth among members. The model offers a partnership to producers, from various sizes of farms, in a project that allows them to play an active role in the production of a local and renewable source of energy while participating directly in the fight against climate change.

The business model, designed to meet the needs of the agricultural community, includes the integrated management of digestates (fertilizing residual materials), customized with the reality of each member and producer and with the regional agricultural context.

Anaerobic Digestion is a biological treatment process whereby microorganisms, in the absence of oxygen, digest organic matter to produce biogas. Once purified, this biogas becomes renewable natural gas (RNG), an energy that is completely interchangeable with conventional natural gas found in Énergir’s gas grid. The revenues generated by the sale of RNG to Énergir allow the viability of such a project.

Farm AD, where manure and slurry are used as main feedstock, is a proven process that is widely used elsewhere in the world, particularly in Europe and the United States. AD offers the advantage to avoid methane emissions into the atmosphere while recovering the energy produced by the decomposition of organic matter.

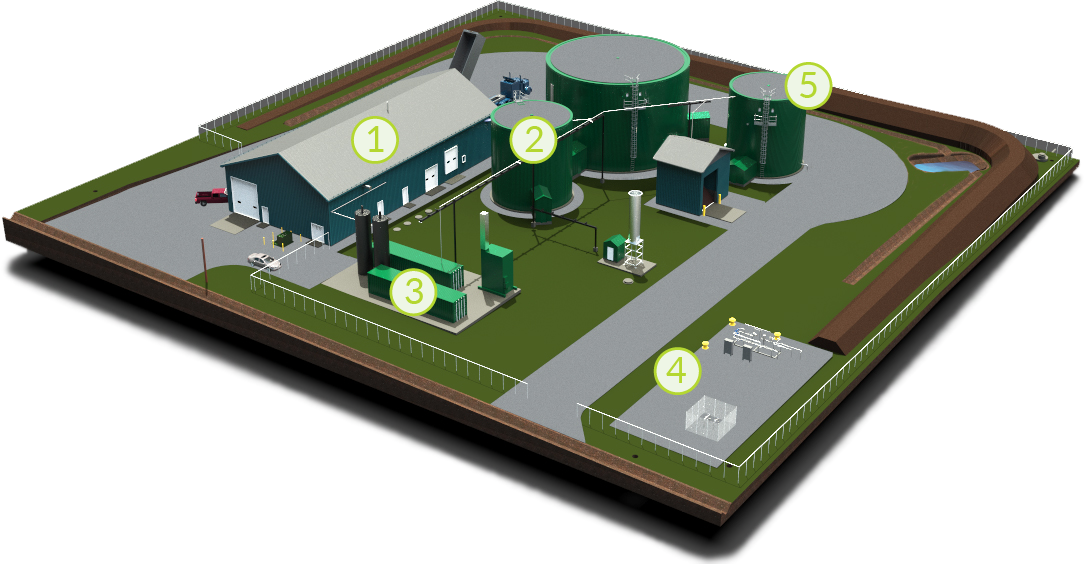

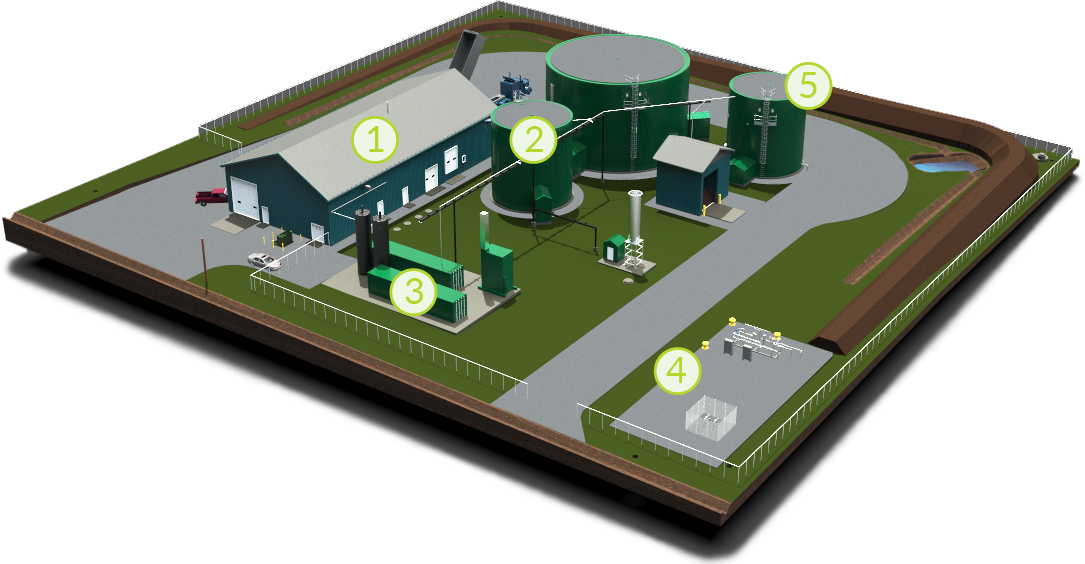

① RECEPTION OF MANURE, slurry and organic residues from surrounding businesses.

② ANAEROBIC DIGESTION of residual materials to produce biogas.

③ PURIFICATION OF BIOGAS to make renewable natural gas (RNG).

④ INJECTION OF RENEWABLE NATURAL GAS (GNR) into Énergir’s gas grid.

⑤ TEMPORARY STORAGE of the digestate (residual fertilizing material) before delivery to members of the cooperative.

Does your business generate residual organic matter?

Thanks to its AD complex, Coop Agri-Énergie Warwick offers you an economic and environmental solution to manage them.

Let us develop a partnership with many benefits.

Contact us at 1 819 469-0657 or biomethane@coopcarbone.coop to find out more about the options available to your farm or business.

Anaerobic Digestion is a reliable process, well-tried throughout the world. Your residual organic materials will be used for the production of renewable natural gas and will then be upgraded as agricultural fertilizers.

The cooperative offers competitive rates for the treatment of your organic materials. Contact us to learn more about the options available to you.

The materials processed by Coop Agri-Énergie Warwick contribute to the reduction of greenhouse gases while being used as fertilizer for farmers in the region. An additional asset is that there will be less odour from farm spreading!

Coop Agri-Énergie Warwick is owned by farmers in the Warwick area. Partnering in such a cooperative allows you to help consolidate both the regional economy and the Québec farming sector.

AirScience is the supplier of the biogas purification technology that has been selected for the project. With more than 25 years of experience in industrial gas and landfill gas purification, AirScience has focused its activities on the production of renewable energy.

Dominion & Grimm Environnement is the supplier of the AD technology selected for the project. Since 2009, Dominion & Grimm Environnement has been building under license the renowned German Lipp digesters installed in more than 1000 sites around the World.